HC-25T C Type Three Guide Column High Speed Precision Press

Main Technical Parameters:

| Model | HC-16T | HC-25T | HC-45T | |||||||

| Capacity | KN | 160 | 250 | 450 | ||||||

| Stroke length | MM | 20 | 25 | 30 | 20 | 30 | 40 | 30 | 40 | 50 |

| Maximum SPM | SPM | 800 | 700 | 600 | 700 | 600 | 500 | 700 | 600 | 500 |

| Minimum SPM | SPM | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Die height | MM | 185-215 | 183-213 | 180-210 | 185-215 | 180-210 | 175-205 | 210-240 | 205-235 | 200-230 |

| Die height adjustment | MM | 30 | 30 | 30 | ||||||

| Slider area | MM | 300x185 | 320x220 | 420x320 | ||||||

| Bolster area | MM | 430x280x70 | 600x330x80 | 680x455x90 | ||||||

| Bolster opening | MM | 90 x 330 | 100x400 | 100x500 | ||||||

| Main motor | KW | 4.0kwx4P | 4.0kwx4P | 5.5kwx4P | ||||||

| Accuracy | JIS/JIS Special grade | JIS /JIS Special grade | JIS/JIS Special grade | |||||||

| Total Weight | TON | 1.95 | 3.6 | 4.8 | ||||||

Main Features:

1.Manufactured from high tensile cast iron, stress relieved for maximum rigidityand long termaccuracy. Ifs the best for continuous production.

2.Double pillars and one plunger guide structure, manufactured from copper bush instead of traditional board for minimize friction. Work with forced lubrication to minimize thermal strain life of the frame, upgrade stamping quality and extend service life of the machine.

3.Balancer device for optional to reduce vibration, make press more precision and stable.

4.It's more convenient to adjust the die with the die height indicator and the hydraulic locking device.

5.HMI is controlled by microcomputer. Display value and fault monitoring system. It is easy to operate.

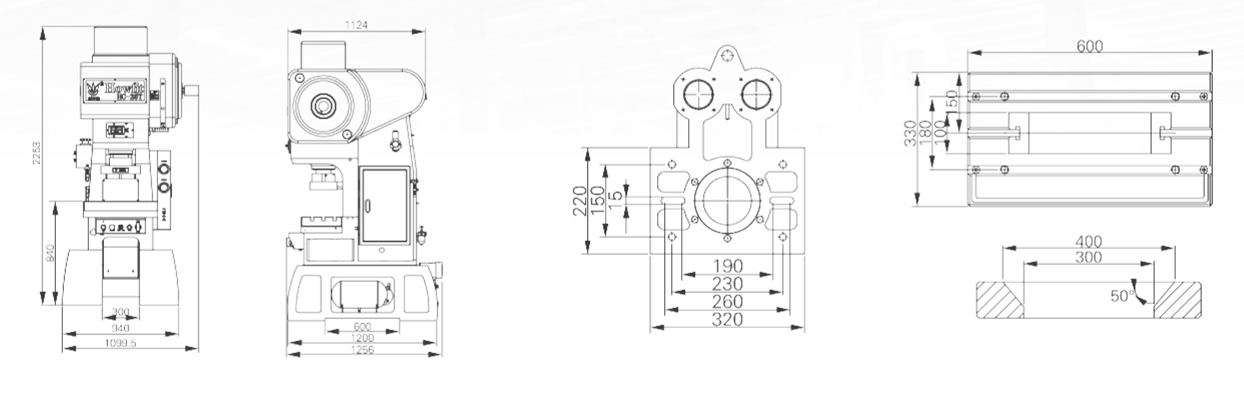

Dimension:

Press Products:

Precautions:

✔ If the edge of punch and concave die is worn out, it's ought to stop using and grind in time. Otherwise, the wear degree of the die edge will be expanded rapidly, the wear of the die will be accelerated, and the quality of the high speed stamping machine and the life of the die will be reduced.

✔ The mould should be put back to the designated position in time after using, and be treated with oil and rust-proof immediately.

✔ To guarantee the service life of the die, the spring of the die should be replaced regularly, which can greatly to prevent the fatigue damage of the spring from affecting the use of the die.

✔ Last but not least, no matter whether you use any dies or not at that time, please kindly ensure your own safety.

FAQ

- Question: Is Howfit A Press Machine Manufacturer Or A Machine Trader?

Answer: Howfit Science and Technology CO., LTD. is a Press Machine manufacturer which specializes in High Speed Press production and sales with an occupation of 15,000 m² for 15 years. We also provides high speed press machine customization service to satisfy your specific requirements.

Question: Is It Convenient To Visit Your Company?

Answer: Yes, Howfit locates in Dongguan city, Guangdong Province, the South of China, where is nearby the main highroad, metro lines, transportation center, links to the downtown and suburbia, airport, railway station and convenient to visit.

Question: How Many Countries Had You Been Successfully Made A Deal With?

Answer: Howfit had been successfully made a deal with Russian Federation, Bangladesh, Republic of India, Socialist Republic of Vietnam, the United Mexican States, The Republic of Turkey, Islamic Republic of Iran, Islamic Republic of Pakistan and etc for so far.

Modal Analysis Of Electric Motor High Speed Lamination Press Crankshaft

- Crankshaft is an important structural part of the press used to transfer motion and power.In the process of work, the load is extremely complex, bearing a huge impact load, in addition, also affected by the role of alternating stress, seriously affect the crankshaft fatigue strength, prone to fatigue failure.With the development of Electric motor high speed lamination press, the load and working conditions of crankshaft are more severe.Under the action of periodic load, the premature fatigue failure occurs.So it is necessary to analyze the dynamic characteristics of crankshaft.