HC-65T C Type Three Guide Column High Speed Precision Press

Main Technical Parameters:

|

Model |

HC-65T |

HC-65TW |

|||

|

Capacity |

KN |

|

600 |

650 |

|

|

Stroke length |

MM |

30 |

40 50 |

30 40 |

50 |

|

Maximum SPM |

SPM |

700 |

600 500 |

600 550 |

500 |

|

Minimum SPM |

SPM |

200 |

200 200 |

200 200 |

200 |

|

Die height |

MM |

215-255 210-250 205-255 |

215-255 210-250 205-255 |

||

|

Die height adjustment |

MM |

50 |

50 |

||

|

Slider area |

MM |

600x400 |

600x400 |

||

|

Bolster area |

MM |

890x540x105 |

890x580x130 |

||

|

Bolster opening |

MM |

120x740 |

150x740 |

||

|

Main motor |

KW |

11kwx4P |

11kwx4P |

||

|

Accuracy |

|

JIS/JIS Special grade |

JIS /JIS Special grade |

||

|

Total Weight |

TON |

7.5 |

9.2 |

||

Main Features:

1.Manufactured from high tensile cast iron, stress relieved for maximum rigidity and long termaccuracy. It's the best for continuous production.

2.Double pillars and one plunger guide structure, manufactured from copper bush instead of traditional board for minimize friction. Work with forced lubrication to minimize thermal strainlife of the frame, upgrade stamping quality and extend service life of the machine.

3.Balancer device for optional to reduce vibration, make press more precision and stable.

4.It's more convenient to adjust the die with the die height indicator and the hydraulic locking device.

5.HMI is controlled by microcomputer. Display value and fault monitoring system. It is easy to operate.

6.Adopt die height adjustment motor, with die height indicator, easy to adjust the die height.

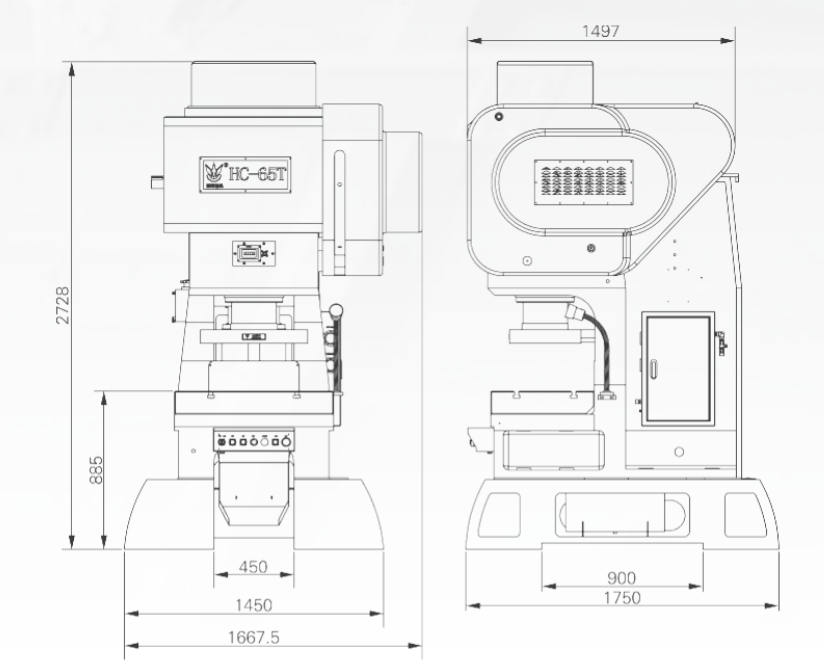

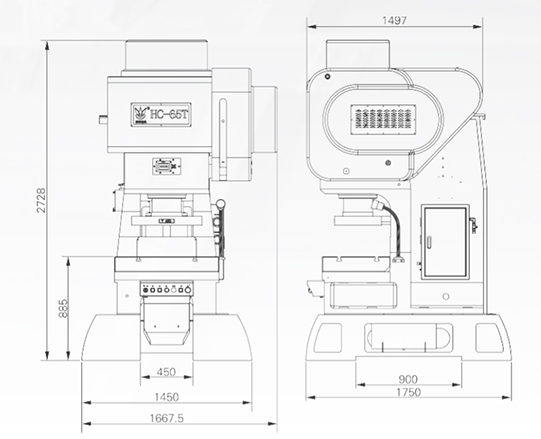

Dimension:

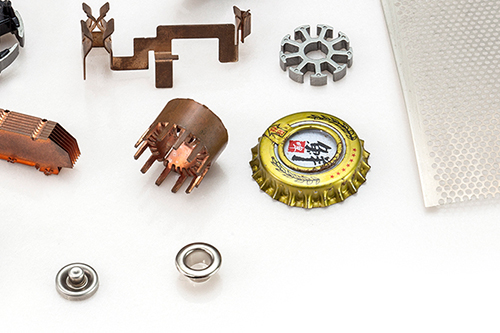

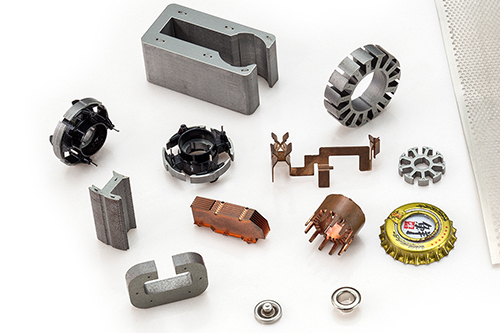

Press Products:

Three Guide Column High Speed Precision Press from 15 ~ 85 tons. For stamping stator and Rotor of ceiling fan, air conditions, lamination for servo motor, sealing motor, geared motor, air conditioner compressor motor, refrigerator compressor, automobile motor, Fan Motor, Ventilation, Refrigeration, Washing Machine Motor, Starter Motor, Engine Cooling Motor, Sunroof Motor, Shaded Pole Motor, HVAC Motor, Electric Turbo Motor, ABS Motor, Tubular Motor, DC Inverter Motor, Segmented, Universal Motor.

FAQ

- Question: Is Howfit A Press Machine Manufacturer Or A Machine Trader?

Answer: Howfit Science and Technology CO., LTD. is a Press Machine manufacturer which specializes in Fan lamination high speed press production and sales with an occupation of 15,000 m² for 16 years. We also provides Fan lamination high speed press customization service to satisfy your specific requirements.

Question: Is It Convenient To Visit Your Company?

Answer: Yes, Howfit locates in Dongguan city, Guangdong Province, the South of China, where is nearby the main highroad, metro lines, transportation center, links to the downtown and suburbia, airport, railway station and convenient to visit.

Question: How Many Countries Had You Been Successfully Made A Deal With?

Answer: Howfit had been successfully made a deal with Russian Federation, Bangladesh, Republic of India, Socialist Republic of Vietnam, the United Mexican States, The Republic of Turkey, Islamic Republic of Iran, Islamic Republic of Pakistan and etc for so far.

Question: What Is The Tonnage Range Of Howfit High Speed Press?

Answer: Howfit had produced Fan lamination high speed press that covers the capacity range of 16 to 630 Tonnage. We had a professional engineer team for research and development in invention, production and after-service.

Shipping And Serving:

1. Global Customer Service Sites:

① China:Dongguan City and Foshan City of Guangdong Province, Changzhou city of Jiangsu Province,Qingdao city of Shandong Province, Wenzhou city and Yuyao city of Zhejiang Province, Tianjin Municipality,Chongqing Municipality.

② India: Delhi, Faridabad, Mumbai, Bengaluru

③ Bangladesh: Dhaka

④ The Republic of Turkey: Istanbul

⑤ Islamic Republic of Pakistan: Islamabad

⑥ Socialist Republic of Vietnam: Ho Chi Minh City

⑦ Russian Federation: Moscow

2. We provide the on-site service in commissioning test and operation training by sending engineers.

3. We provide free replacement for the faulty machine parts during the warranty period.

4. We guarantee the solution would be given within 12 hours if malfunction come up to our machine.

What is the difference between Fan lamination high speed press Machine and ordinary Press Machine? In many mechanical industries, Press is an indispensable tool for mould / lamination production. There are a lot of types and models of presses. Therefore, what are the differences between High Speed Presses and ordinary presses? Is it the speed differed these two? Is Fan Lamination High Speed Press better than ordinary?What is the difference between high speed press and ordinary punch? Mainly the difference of High-speed Press is its precision, strength, speed, system stability & construction operation. The Fan lamination high speed press are more specific and high-standard than the ordinary punch, and high requirements. But is not a Fan Lamination High Speed Press than ordinary punching machine. During the purchasing, it also depends on the application, if the stamping speed is under 200 strock per minute, then you might choose ordinary punching machine or more affordable. Here are the main differences between Fan lamination Fan Lamination High Speed Press and ordinary punch.

Product Advantages

- High speed press for EI lamination is suitable for EI sheet stamping. EI precision punch is a powerful tool for mass production of EI. As long as the manufacturer matches a set of dies first, it can stamp out continuously on the precision punch. It has the advantages of high speed, high precision, economical benefit and wide utilization.

High speed press for EI lamination can be equipped with automatic feeders of different grades and specifications for automatic production. Through a reasonable product mix, it is convenient to realize the production mode of one person managing multiple machines.

The machine structure consists of high rigidity casting iron, which guarantee the stability, the accuracy and the long-term usage. With the forced lubrication, the thermal deformation would be minimized. The double pillar and one plunger guide was made of brass and it reduced the friction to the minimum. Balance weight for optional to reduce vibration. HMI is controlled by microcomputer. With the advanced computer controller, Howfit Presses are using unique design stamping operation software. The computer has strong function and large memory capacity. With the guidance parameter setting, it has the function of fault revelation and makes the mechanical operation simpler.