The quality control centre is being served with advanced testing equipment and professional monitor methods.

Quality is the foundation of an enterprise, and high quality products are the core competitiveness of an enterprise. In order to manufacture high quality and high precision products, HOWFIT strictly controls every gate in the manufacturing process from feeding to manufacturing to shipping inspection to ensure the quality of each punch press.

EQUIPMENT

① All the cast parts of our punch presses are treated with aging, and after rough machining, they are treated with vibration aging and then finish machining, so as to reduce and homogenize the residual stress, so that the punch press can maintain dynamic stability and improve the anti-deformation ability of the parts.

② Adopting the laser tracking tester from API, USA, to inspect the quality of large spare parts bed and slide, which further improves the quality of the products.

③ Adopting Japan Mitutoyo coordinate tester for quality inspection of parts with high precision requirements, which provides guarantee for the quality of high precision parts.

④ Adopt Swiss TRIMOS secondary tester with marble platform for full inspection of small parts, strictly control every link.

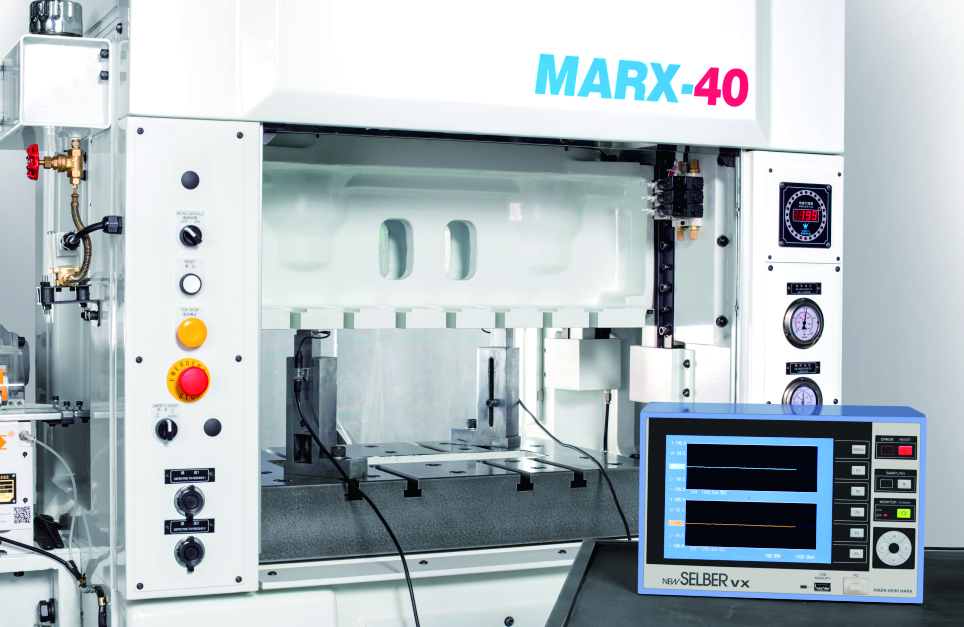

⑤ Adopt Japan RIKEN BDC monitor to test the stability performance of the BDC of the press machine.

⑥ Adopt Japan RIKEN tonnage tester to test the press capacity of press machine.