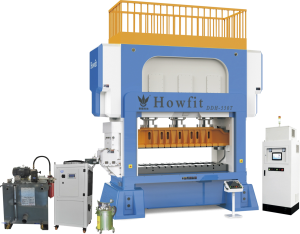

The DDH HOWFIT High Speed Precision Press is a high-efficiency, high-precision stamping processing equipment, which is widely used in the stamping production of parts in industries such as automobiles, electronics, and home appliances. This article will discuss the mechanical structure, control system, blanking principle and technology development trend of the equipment in depth from the perspective of engineering technology.

1. Mechanical structure

The basic mechanical structure of the gantry-type high-speed precision punching machine includes four parts: the fuselage, the punching machine, the mold and the feeding system. Among them, the fuselage is supported by two upper and lower gantry-type cast iron frames, the upper part is connected with the punching machine through guide rails and sliders, and the lower part is the base of the feeding system. The punch press is the core component of the machine, which is composed of a punch frame, a crankshaft transmission mechanism, a connecting rod transmission mechanism and a needle bar mechanism. The mold is a tool for punching target parts, which consists of a mold frame and upper and lower modules. The feeding system is composed of a feeding mechanism and a feeding table, which undertakes the task of conveying materials to the mold.

The overall structure of the machine adopts the gantry structure, which has the characteristics of high strength and high bearing capacity, so that it can maintain stability and high precision during high-speed punching. In addition, the mechanical structure also adopts multi-channel strengthening process to make the machine more stable and durable in use.

2. Control system

The control system of the gantry-type high-speed precision punching machine consists of two parts: hardware and software. The hardware mainly includes servo motors, controllers, sensors, etc., and the software is the program running on the controller, which is responsible for realizing various control functions. The control system mainly completes the automatic production of the machine through three aspects: motion control, pressure control and blanking control. It is worth mentioning that the impact control technology in the control system can realize high-speed, high-efficiency, and high-precision stamping processing, ensuring production quality and efficiency.

3. Punching principle

The punching principle of the gantry high-speed precision punching machine is to shape the material through the punching machine. Specifically, the crankshaft transmission mechanism of the machine transmits the power provided by the motor to the needle bar mechanism, so that the needle bar moves back and forth. When the needle bar is pressed down, the boss in the mold is connected with the needle bar, causing the module to fall until it collides with the upper module. At the moment of the collision, the die exerts supersonic force and punches the material into shape. During the punching process, multiple parameters need to be controlled, such as punching speed, strength, punch position, etc., to ensure the accuracy and efficiency of punching and forming.

4. Technology development trend

At present, with the continuous advancement of science and technology and the continuous demand of the market, the mechanical structure, control system and punching principle of the gantry-type high-speed precision punching machine are constantly innovating and evolving. Specifically, technological development trends include the following aspects:

1. Improvement of precision and speed: With the continuous development of electronic control technology, servo technology and impact control technology, the gantry-type high-speed precision punching machine will become faster and more accurate.

2. Increased automation: With the rise of intelligent manufacturing, the application of gantry-type high-speed precision punching machines in machine automation and digitalization will continue to increase.

3. Improvement of the system: The control system and mechanical structure of the gantry-type high-speed precision punching machine will be continuously improved and optimized to meet the market’s demand for high-efficiency, high-quality, and low-cost production.

5. Case comparison

Taking punching auto parts as an example, the speed of traditional CNC punching machines is generally 200-600 times per minute, while the speed of gantry high-speed precision punching machines can reach more than 1000 times per minute. Therefore, the use of gantry-type high-speed precision punching machines can greatly improve production efficiency. In addition, the precision of the gantry-type high-speed precision punching machine is much higher than that of the traditional CNC punching machine, and it can die-cut more detailed and complex parts. Therefore, in the field of production that requires high precision and high speed, the gantry-type high-speed precision punching machine has greater advantages and application prospects.

Post time: Jun-14-2023