HOWFIT: Powering the Global Transformation of Intelligent Manufacturing with High-Speed Precision Press Technology

In the field of high-end equipment manufacturing, high-speed precision presses stand as a core indicator of a nation’s level of industrial automation and precision manufacturing. These machines act as the “heart” of modern industrial production, delivering exceptional running speeds, micron-level positioning accuracy, and outstanding stability to continuously power critical sectors such as electronics, automotive, and new energy. Guangdong Howfit Science And Technology Co., Ltd. (HOWFIT), headquartered in Dongguan, a key manufacturing hub in China, is a leader in this specialized field with nearly two decades of dedication. Since its establishment in 2006, HOWFIT has consistently focused on the research, development, and manufacturing of high precision press and intelligent stamping solutions. It has not only driven technological iteration and upgrades domestically but has also successfully exported the precision power of “Intelligent Manufacturing in China” to global markets.

1. The Technological Foundation: The Fusion of Precision, Speed, and Stability

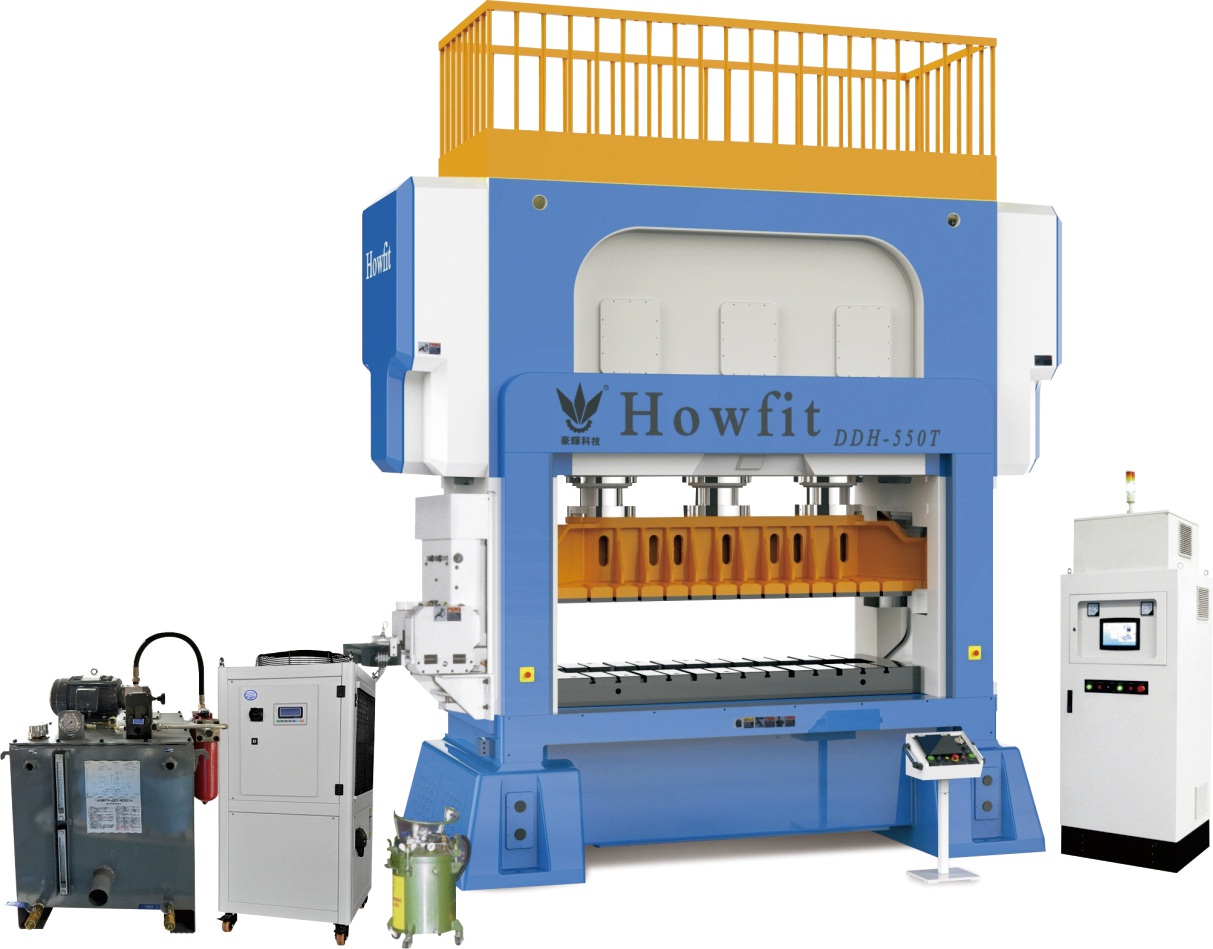

HOWFIT’s core competitiveness is rooted in its relentless pursuit of the ultimate performance in the key technical parameters of high-speed precision presses and its profound understanding of long-term equipment reliability. The company’s product line is extensive, covering capacities from 25 to 500 tons, meeting diverse stamping needs ranging from precision terminals to large motor stators and rotors.

Taking a typical HOWFIT high-speed precision press as an example, its technological essence is reflected in several dimensions:

✅ Ultra-High Operational Efficiency: The machines achieve stroke speeds of 100 to 700 strokes per minute (SPM), with some high-performance models capable of high-frequency stamping at 450 SPM under 300-ton pressure, significantly enhancing production efficiency.

✅ Exceptional Rigidity and Accuracy: The unique gantry-style structure and multi-round column (e.g., six-round, four-round) designs ensure superior stability and vertical precision of the slide block during high-speed operation, which is the fundamental guarantee for production consistency.

✅ Intelligence and Integration: Modern manufacturing competition is no longer just about individual machines but about complete solutions. HOWFIT provides integrated intelligent stamping lines, including high-speed presses, robotic feeders, and electronic leveling/uncoiling machines. This integrated approach minimizes equipment compatibility issues and achieves full-process automation from coil material to finished product.

HOWFIT’s technological strength has earned high recognition from both capital markets and the industry. The company was listed on the New Third Board (NEEQ) in 2017 (Stock Code: 870520) and has since been awarded titles such as “National High-Tech Enterprise” and “Guangdong Contract-Honoring & Creditworthy Enterprise,” providing a solid foundation for its continuous R&D and innovation.

2. Market Depth: From Local Innovation to Global Empowerment

HOWFIT’s vision has never been limited to the domestic market. The company’s internationalization strategy is clearly evident in its global supply chain and market layout. Public trade data shows that HOWFIT’s products have been consistently exported to important overseas markets like India, establishing long-term cooperative relationships with well-known local purchasers. For instance, its HC-25 ton high-speed press, along with auxiliary equipment like feeders and uncoilers, has become a reliable choice on the production lines of international clients.

Behind this global footprint is HOWFIT’s precise grasp of global manufacturing trends. Whether it’s the miniaturization of consumer electronics or the massive demand for efficient motors (stators & rotors) in the new energy vehicle sector, all rely on high-speed precision stamping technology. Leveraging its technological accumulation, HOWFIT is deeply involved in the construction of these global industrial chains.

Table 1: Representative HOWFIT High-Speed Precision Press Products and Application Fields

| Product Series / Model | Nominal Force (Capacity) | Typical Stroke Speed (SPM) | Core Structural Features | Primary Application Fields |

|---|---|---|---|---|

| HC Series | 25 Ton | Data not publicly specified | Equipped with robotic feeding system | Precision electronic terminals, lead frames |

| DDH Series | 65 Ton | 150-700 | C-frame or Gantry style | Metal lamination, general precision stamping |

| DDL Series | 300 Ton | 100-450 | Gantry-style high-rigidity structure | Motor stators & rotors, large mesh plates, automotive components |

| Gantry Multi-Round Column Series | Various capacities | High-speed | Six-round / Four-round column design | Precision stamping requiring high accuracy and stability |

3. Industry Outlook: The Future Path of Intelligence and Sustainability

Currently, the waves of Industry 4.0 and sustainable development are reshaping the equipment manufacturing industry. The high-speed presses of the future will not only be “faster and more precise” but will become intelligent entities deeply integrated with sensing, data analytics, and adaptive control. For example, integrating high-precision force-displacement monitoring systems into the pressing process can ensure the quality of every single product in real-time and achieve digital traceability of the manufacturing process. While this represents a cutting-edge industry trend, it also points the way for future R&D direction of leading enterprises like HOWFIT—shifting from providing standalone equipment to offering full-process intelligent solutions encompassing condition monitoring, predictive maintenance, and process optimization.

Simultaneously, as global energy efficiency requirements increase, developing energy-saving motor drives and optimizing equipment energy consumption structures will become crucial topics in the iteration of high-speed press machine technology. HOWFIT’s strategic location near the geometric center of the Pearl River Delta facilitates the integration of supply chain resources. Its responsiveness to future trends will determine its position in the next phase of competition.

Conclusion

From the manufacturing workshops in Dongguan to the intelligent production lines of global clients, HOWFIT has, over nearly twenty years, written a microcosm of independent innovation and global breakthrough for China’s high-end equipment. Under the eternal of “speed” and “precision,” HOWFIT, through solid technological accumulation and forward-looking market strategies, has not only consolidated its leading position in the domestic high speed precision stamping sector but has also successfully integrated into the global value chain. Looking forward, as the industry transformation driven by intelligence and sustainability deepens, HOWFIT—with its continued commitment to innovation and deepening of solution capabilities—is poised to play an even more critical role in advancing the transformation and upgrading of global precision manufacturing.

Post time: Dec-06-2025