Well, for the return on investment and the cost of use, the cost of the DDH HOWFIT High Speed Precision Press is very important during the use process, including the original price of equipment, operating costs, maintenance costs, spare parts costs, labor costs, etc. If these costs can be effectively controlled, the cost of using the equipment will be greatly reduced, and the return on investment will be more impressive.

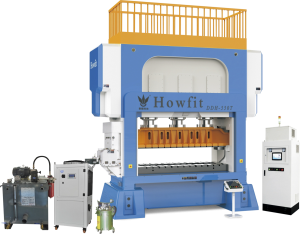

First look at the original price of the equipment. At present, suppliers who can provide gantry-type high-speed precision punching machine manufacturing equipment are relatively scarce in the market, so the price is naturally relatively high. The price of a small and medium-sized model of equipment is generally around hundreds of thousands of yuan. But compared to its highly automated and efficient performance, the return on investment of this equipment is also very impressive.

The second is operating costs. The operating cost of the gantry-type high-speed precision punching machine is mainly composed of electricity, wages, consumables, etc. Because of the equipment’s compact structure, small size, long service life and simple operation, the operating cost is relatively low. Moreover, the high-speed punch can quickly complete a large number of processing tasks during operation, greatly improving work efficiency and reducing processing costs. In addition, the energy consumption of high-speed punching machines is relatively low, which greatly improves the efficiency of using electric energy compared with traditional punching machines.

The third is maintenance costs. The overall structure of the gantry-type high-speed precision punching machine is relatively simple, and the equipment has certain intelligent maintenance functions, which reduces the burden of equipment maintenance. However, equipment spare parts and maintenance costs are also a cost to consider, because if these costs are too high, they will seriously increase the cost of use. Therefore, the choice of maintenance costs should be jointly negotiated between the control department of production materials and the equipment management department to ensure that the cost is controlled under the premise of ensuring the good operation of the equipment.

Regarding the cost of spare parts, the components of the gantry type high-speed precision punching machine are relatively concentrated, so the cost of spare parts is relatively low. However, it should be noted that before purchasing equipment, it is necessary to learn from the supplier about the after-sales service they provide, so as to ensure that the equipment can be repaired in time when it fails during use.

The last is labor cost. The gantry-type high-speed precision punching machine is very easy to operate, and compared with the traditional punching machine, it has a higher degree of automation, which breaks away from the requirements for the skill level of the operator. Moreover, the high-efficiency performance of the equipment also greatly improves the production efficiency of the operator, reduces the number of workers and working hours, and the labor cost is relatively low.

In terms of market demand and potential profits, gantry-type high-speed precision punching machines are suitable for a variety of industries and fields, mainly used in electronics, automobiles, medical equipment, communication equipment and other fields. In these fields, the manufacturing quality of parts has a very important influence on the performance and quality of products, and the precision requirements of these parts are usually very high. Therefore, there is a great market demand for gantry-type high-speed precision punching machines with high precision and high speed in these fields.

At the same time, with the development of science and technology and the market’s higher and higher requirements for product quality, the scope of use of gantry-type high-speed precision punching machines is also expanding. Compared with traditional punching machines, high-speed precision punching machines are better matched, more flexible, intelligent and automatic, which makes it have a broader application prospect in the market. Taking the processing of auto parts as an example, they have very high precision requirements and require thousands of high-speed precision punching machines for production, which makes the gantry-type high-speed precision punching machines have huge potential profits in this field.

Finally, compared with traditional CNC punching machines, gantry-type high-speed precision punching machines have lower operating costs, higher work efficiency, longer service life, and more controllable maintenance and spare parts costs. In the future development trend, as people’s requirements for product precision are getting higher and higher, the market share of gantry-type high-speed precision punching machines will also continue to increase.

In general, the return on investment of the gantry-type high-speed precision punching machine is very impressive, and the return on investment can be realized in a short period of time. Although the original price of the equipment is high, its various use costs and maintenance costs are small. If it is correctly applied and managed reasonably, the market prospect and potential profit of the gantry high-speed precision punching machine are also very broad.

Post time: Jun-15-2023