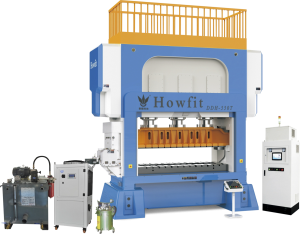

As an advanced manufacturing equipment, the Howfit 200-ton high-speed precision punching machine has the advantages of high-efficiency production and precision machining, and is widely used in auto parts, electrical parts and other fields. From an economic and financial point of view, this article will discuss in detail the return on investment, use cost and maintenance of a 200-ton high-speed precision punching machine, and compare it with specific cases and traditional punching machines.

1. Analysis of return on investment:

cost of investment:

The price of a 200-ton high-speed precision punching machine is relatively high, usually ranging from hundreds of thousands to millions of yuan, depending on the equipment brand and configuration. In addition, a certain amount of human resources are needed for operation and maintenance.

Production efficiency improvement:

The high-speed precision punching machine has high working efficiency, and the number of strokes can reach 150-600 times per minute. Compared with the traditional punching machine, it can greatly improve the production efficiency and output. This will further reduce unit product cost and enhance the competitiveness of enterprises.

Precision Machining Capability:

The high-speed precision punching machine has high precision and stability, which can achieve higher precision and consistency in parts processing, reduce the defective rate, and thus save material and labor costs.

Market demand analysis:

Taking the automobile industry as an example, with the rapid development of the automobile industry and the improvement of precision requirements for parts, the demand for high-speed precision punching machines continues to increase. Similar market demands also exist in fields such as electrical components. Therefore, investing in high-speed precision punching machines is expected to usher in more orders and profit opportunities.

case analysis:

Taking an auto parts manufacturing company as an example, after the company introduced a 200-ton high-speed precision punching machine, the production efficiency increased by 50%, and the product quality was significantly improved. In terms of investment cost recovery, it is estimated that the cost return can be realized within 3 years, and considerable economic benefits can be obtained in the next few years.

Second, the use of cost analysis:

Labor costs:

The operation of high-speed precision punching machines is relatively complicated and requires certain training and skill improvement. Therefore, enterprises need to invest a certain amount of human resources for operation and maintenance. Labor costs include training costs, wages and social insurance, etc., and reasonable cost control is required.

Energy costs:

The main engine motor of the high-speed precision punching machine has a high power and consumes a considerable amount of electric energy during use. Therefore, enterprises need to manage energy costs reasonably, adopt energy-saving measures, and reduce energy waste.

Maintenance cost:

Maintenance is an important link to ensure the normal operation and stability of equipment. According to the manufacturer’s recommendations, measures such as keeping the equipment clean, adding butter, and regularly changing the circulating oil of the machine can reduce maintenance costs and prolong the life of the equipment.

3. Maintenance analysis:

Equipment kept clean:

Regularly clean the key parts such as the center column, slider guide column and mold bottom plate to avoid damage to the equipment caused by dirt. At the same time, keep the cleanliness of the work surface to avoid scratches and affect production.

Add butter:

Butter needs to be added to the flywheel of the high-speed precision punching machine, especially when the equipment is first used within one month. Long-term non-greasing may cause internal wear of the flywheel and affect equipment performance. Therefore, regular filling of high-temperature butter is a necessary maintenance measure.

Machine cycle oil replacement:

According to the service time of the equipment and the requirements of the manufacturer, the circulating oil of the machine is replaced regularly to ensure the normal operation and processing accuracy of the equipment.

in conclusion:

Based on economic and financial analysis, the rate of return for investing in a 200-ton high-speed precision punching machine is relatively high. Improving production efficiency, precision machining capability and meeting market demand are the main advantages. In terms of cost of use, it is necessary to reasonably control labor costs and energy costs. In terms of maintenance, it is necessary to keep the equipment clean, add butter and regularly replace the circulating oil of the machine. Through reasonable investment and maintenance, high-speed precision punching machines can bring considerable economic benefits and competitive advantages to enterprises.

Post time: Jul-04-2023