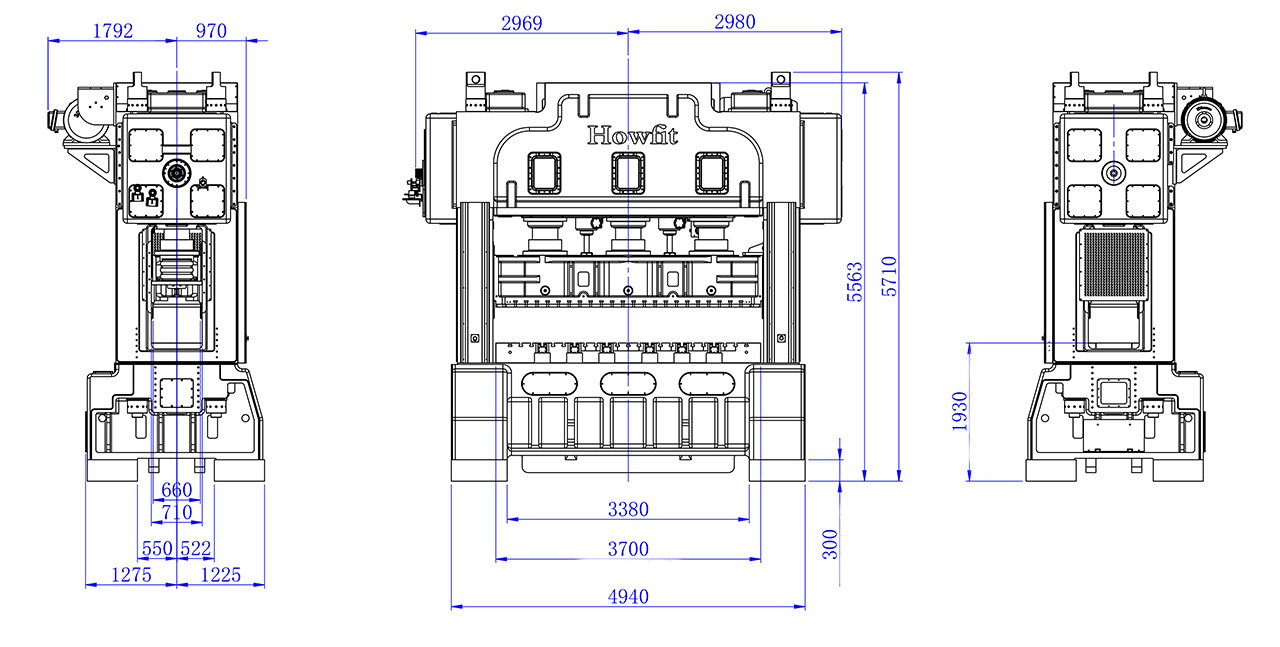

HOWFIT DDH 400T ZW-3700 High-Speed Precision Punch Press Technical Innovation and Configuration Analysis

Introduction

“DDH 400T ZW-3700″ high-speed precision punch machine is a piece of equipment that exhibits excellent performance in the field of punch presses. This article will comprehensively analyze the overall overview of this punch press, highlight its performance in technological innovation, and deeply explore the advantages and application scenarios of its many configurations.

Overall Overview of the Machine

“DDH 400T ZW-3700″ punch press adopts a three-stage combined structure, which is tightened by twice the nominal force. It has excellent overall rigidity and the deflection value is strictly controlled at 1/18000, laying a solid foundation for its stable operation. The fuselage is made of high-quality alloy castings, which have undergone stress relief treatment and have excellent vibration damping performance, ensuring long-term high-precision operation. Through finite element analysis, the key castings have reasonable stress and small deformation, providing solid structural support for the punch press.

Technology Innovation Analysis

1. Servo motor mold height adjustment

“DDH 400T ZW-3700″ introduces servo motor mold height adjustment technology. Through precise motor adjustment, the mold height can be adjusted in real time. The application of this technology enables the punch press to achieve a high degree of mold accuracy in high-speed operation, thereby improving production efficiency and product quality.

2. Digital mold height indicator

The digital mold height indicator provides operators with intuitive height information and monitors the position of the mold in real time. The application of this technology not only simplifies the operation process, but also improves work efficiency, reduces the difficulty of operation, and provides users with a better experience.

3. Prestressed eight-sided circulating needle roller guide

The slider adopts prestressed eight-sided circulating needle roller guide to ensure the verticality and parallelism of the slider’s up and down movement. Needle roller bearings have large load capacity, high precision, easy maintenance, and long life, making the mold production cycle longer and more durable. This design performs well during high-speed stamping processes, ensuring the stability and efficiency of the punch press.

4. Inverse symmetrical dynamic balancing device

“DDH 400T ZW-3700″ adopts an inverse symmetrical dynamic balancing device to balance the horizontal and vertical inertial forces generated during operation, making the entire machine run more smoothly. This innovative design reduces vibration and noise during high-speed operation, improving equipment reliability and operational safety.

5. High speed and heavy load sliding bearing structure

The connecting rod and the six-point super close-range support part adopt a high-speed and heavy-load sliding bearing structure, which has good force rigidity and makes it easier to ensure the accuracy of the bottom dead center during the stamping process. The three-point large-diameter center guide pillar sliding guide ensures the smoothness of the stamping operation of the slider to the greatest extent and ensures that the three-point force acts evenly on the slide seat.

6. Split design of brake and clutch

The split design of brake and clutch is adopted to balance the force on the left and right sides of the punch press and reduce the unilateral stress on the left and right bearing parts. This design improves the stability of the equipment, reduces maintenance costs, and extends the service life of the equipment.

Configuration Analysis

1. Hydraulic slider fixing device

The hydraulic slider fixing device uses advanced hydraulic technology to firmly fix the slider, ensuring stability during high-speed operation and reducing equipment vibration and noise.

2. Lubricant constant temperature cooling + heating device

The lubricating oil constant temperature cooling + heating device ensures that the lubricating oil is always maintained within a suitable temperature range during the operation of the punch press, effectively reducing friction and wear and extending the service life of equipment parts.

3. Safety grating and front and rear safety door devices

The safety grating and front and rear safety door devices build a comprehensive safety protection system to ensure the safety of operators during use. These devices can detect abnormal situations in time and take corresponding safety measures to ensure the safety of the working environment.

in conclusion

“DDH 400T ZW-3700″ high-speed precision punch machine has become a leader in the field of punch machines with its excellent overall design and technological innovation. The application of many advanced technologies and the combination of reasonable configuration make it perform well in high-speed stamping production and inject new impetus into the manufacturing industry. With the continuous development of manufacturing technology, “DDH 400T ZW-3700″ will surely show better performance in the future and bring more possibilities to the industrial field.

In Conclusion

“DDH 400T ZW-3700″ high-speed precision punch machine has become a leader in the field of punch machines with its excellent overall design and technological innovation…

For more details or purchasing inquiries, please contact:

howfitvincentpeng@163.com

sales@howfit-press.com

+86 138 2911 9086

Post time: Apr-11-2024